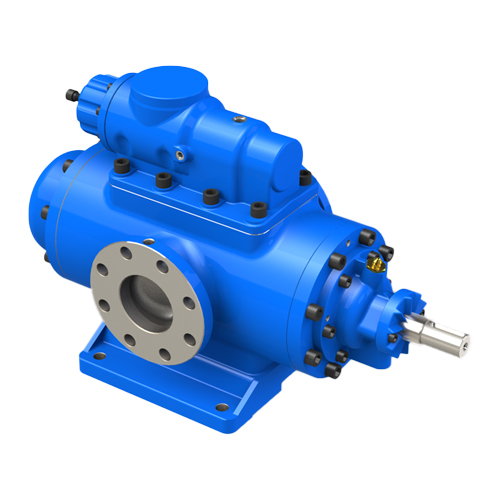

Rotary Triple Screw Pump Manufacturer

Dev Engineers is a leading manufacturer and supplier of Rotary Triple Screw Pump & Triple Screw Pumpin Ahmedabad, Delhi, Mumbai, Kolkata, Chennai, Bangalore, Indore, Ludhiana, Pune, and Coimbatore.

Being Rotary Triple Screw Pump manufacturer, we provide excellent quality. Our triple screw pumps are manufacturered using a premium quality material for accurate and speedy functioning.

Working Principle

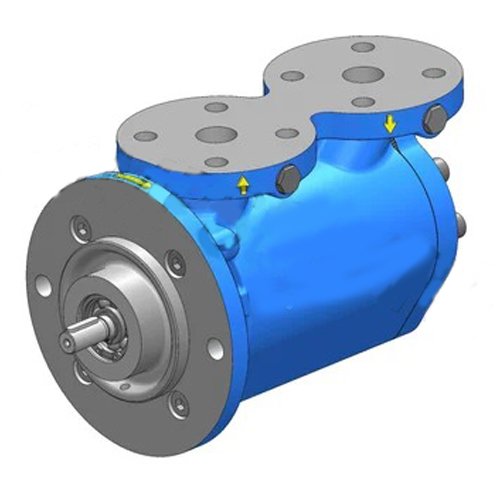

Triple Screw Pumps are rotary positive displacement type pumps. Three rotating screws are present triple screw pump. By the meshing of the three rotating screws and the enclosing pump casing the displacement effect of fluid is created. The screws are radially supported by the sliding contact in the casing, which requires lubrication by the pumped liquid.

Features of Triple Screw Pump

- The TH- Series three-screw pump consist one rotor and two idlers, in a precisely bored pump casing insert, which ensures high pumping efficiency and high suction power.

- As the double-start screws meshes, a continuous axially moving voids/pockets generate, which traps the liquid inside it, and hence transfers the fluid, where it required.

- These pumps permits an even axial flow without pulsation and silent pumping operation even at a high speed.

- Axial loads on the rotor are often compensated by an adequate design of the bearing and all the radial forces are self-compensated.

- Further, size of a rotor kept small in the design, which enables these pumps to run at a higher speed with direct coupling to the prime mover.

- As the double-start screws meshes, a continuous axially moving voids/pockets generate, which traps the liquid inside it, and hence transfers the fluid, where it required.

These pumps permit an even axial flow without pulsation and silent pumping operation even at a high speed. Axial loads on the rotor are often compensated by an adequate design of the bearing and all the radial forces are self-compensated.

Further, size of a rotor kept small in the design, which enables these pumps to run at a higher speed with direct coupling to the prime mover. Self-compensated radial forces eliminate need of bearing High pressure capacity up to 40 Bar Self-Priming and reversible cartridge design simplifies maintenance problem and saves lead time.

Applicaions of Rotary Triple Screw Pump

- Positive Displacement Pump

- High running speed with less noise

- Long service life and minimum maintenance

- Axial smooth flow without churning

- High suction power

- Self-compensated radial forces eliminate need of bearing

- High pressure capacity up to 40 Bar

- Self-Priming and reversible

- Cartridge design simplifies maintenance problem and saves lead time

Material of Construction

| Casing Design | : Casting, Fabricated SS, Custom |

| Casing | : Cast Iron, Carbon Steel, Stainless Steel, Special material |

| Casing Insert | : Cast iron, Aluminum Alloy, Copper, Special material |

| Rotor | : Alloy Steel, Hardened Steel, Surface Treated Steel, Special material |

| Idler | : Hardened Steel, Surface Treated Steel, Special material |

| Relief Valve Parts | : In steel and Cast Iron |

Installation Features

| Bearing | : External or Internal |

| Sealing Option | : Mechanical Seal, Gland packing, Lip Seal, Cartridge seal, Custom. |

| Mounting | : Horizontally or vertically or pedestial |

| Direction of rotation | : CW(standard), CCW(on request) |

| Ports location | : Radial or axial inlet and radial outlet |

| Relief valves | : Built-in, Line mounted, No RV |

| Jacketing Option | : Full, Partial, No Jacket |

| Driving unit | : Direct Couple OR Gear Box OR Pulley Drive with Prime Mover |

| Relief valves | : Built-in, Line mounted, No RV |

Applications of Rotary Triple Screw Pump

Industries Where it Used

- Power Hydraulics

- Power Generation

- General industries

- Power Hydraulics

- Machine tools

- Windmill

- Oil and Gas

- Compressor Lubrication

- Presses

- Marine

- Filtration

- Chemical and Petro-chemical industries

- Offshore Engineering

USED in Liquid Media

- Bunker Oil

- Furnace Oil

- Hydraulic oils

- Mineral oil

- Engine Oil

- Heating Oil

- Synthetic Oil

- Oil water Emulsions

- Fuel Oil

- Diesel Oil

- Cutting and coolant Oils

- Tar Oils

- Paint

- Bitumen

- lacquers

PRODUCTS

- Economy RGP/RGX Series

- Heavy Duty DERB/DERN

- Heavy Duty DEW

- Stainless Steel Gear Pumps –DGPSS / SUS

- High Viscous Gear Pumps-HVG

- Fuel Injection DFIG

- Rotary Trachodial Pump DIL

- Internal Gear Pumps with Crescent-DIC

- SS Tri Lobe Pumps Economy – DELB

- Rotary Shuttle Block Pump

- Progressive Cavity Screw Pumps

- Twin Screw Pumps

- Triple Screw Pumps

- Stainless Steel Hand Operated Rotary Barrel / Drum Pumps