DIC Pump Manufacturer

Dev Engineers, a premier manufacturer and supplier of DIC Pump in Ahmedabad, Delhi, Mumbai, Kolkata, Chennai, Bangalore, Indore, Ludhiana, Pune, and Coimbatore.

“DEVPUMPS” DIC- Series Pump are Simple In Design and construction. They are built in various sizes and versions to suit every possible industrial applications. The DIC-Series Pump are specially designed for handling liquids with very law viscosity and very high viscosity , free from abrasive particles and corrosive substances. These pumps have proved themselves dependable & efficient in many types of industrial applications. They handle liquids ranging from light, volatile, liquefied gases to heavy viscous liquids and semi-solids.

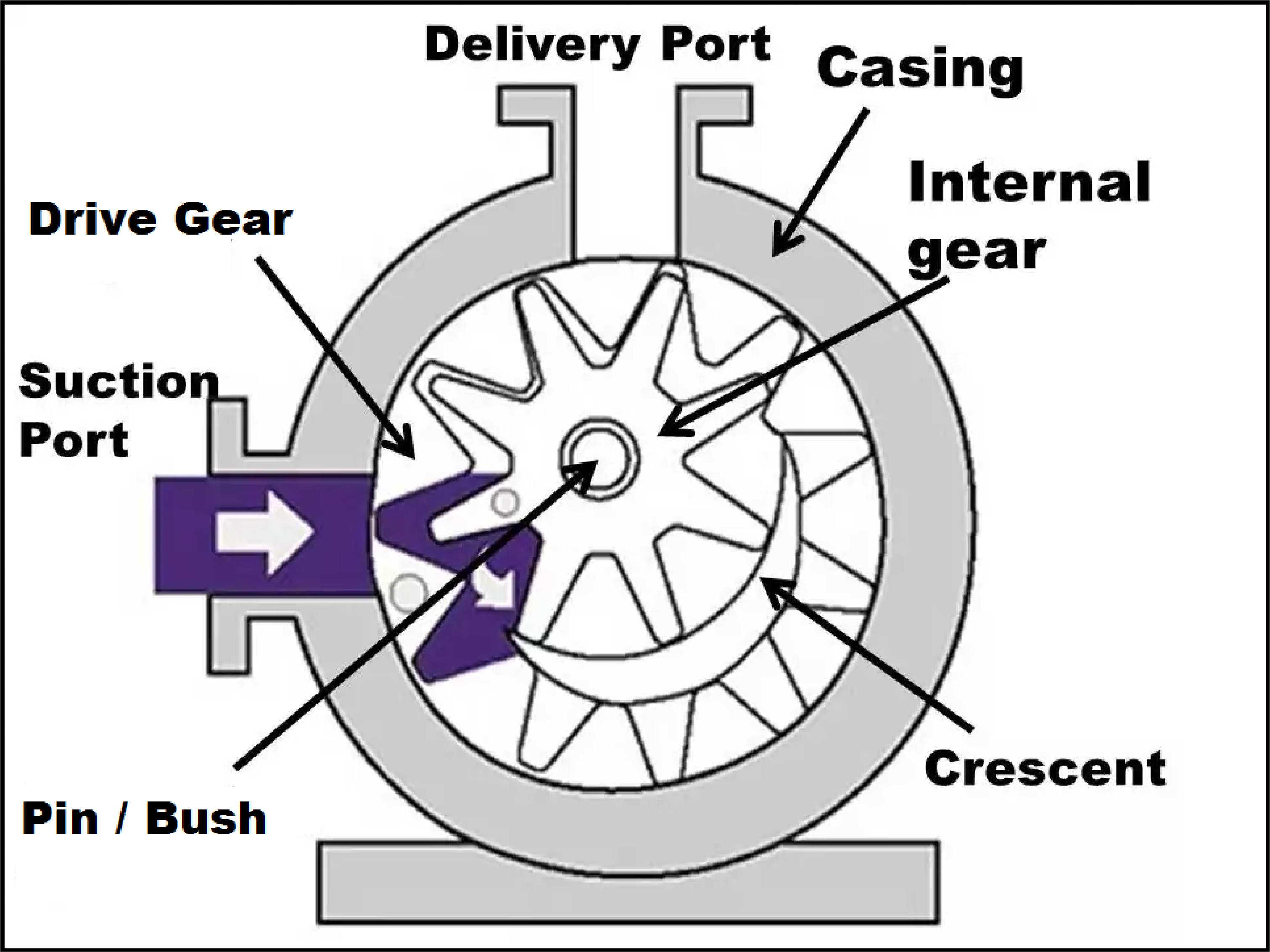

Only Two Moving Parts

“DEVPUMPS” DIC-Series Pump have only two moving parts means a gear within a gear. Positive displacement of liquid is accomplished by the filling of the spaces between the teeth of the rotor and idler gears. The only limiting factor to peak performance in an gear pump is that the liquid pumped should be comparatively clean.

Working

With every revolution of the pump shaft a definite amount of liquid enters the pump through the suction port. The liquid fills the spaces between the teeth of the rotor and the idler . The crescent on the pump head splits the flow of liquid as it is moved smoothly towards the discharge port.

The Idler gear, which carries the liquid between its teeth and the inside surface of the crescent, rotates on the pin supported by the pump head . The rotor gear, which carries the liquid between its teeth travels between the casing and the outside surfaces of the crescent and is connected to the pump shaft.

Drive

These gear pumps are suitable for either direct drive through flexible coupling or V-belt drive or through gearbox drive or through variable speed drive.

Suction Lifts

These gear pumps are suitable for suction lift up to 25 feet ( depending upon braking point of volatile liquids ) Heavy viscous liquids are readily handled reduction in speed from standard ratings . Capacity is corresponding reduced.

Technical Specifications

| Sr. | Pump Model | Pump Size In BSP Screw End | Capacity in Litters /Minute 1440rom | Pressure Max. In Kg/cm2 |

|---|---|---|---|---|

| DIC-050 | ½” x ½” | 10 | 1440 | 16 kg/cm2 |

| DIC -075 | ¾” x ¾” | 40 | 1440 | 16 kg/cm2 |

| DIC -100 | 1” x 1” | 50 | 1440 | 16 kg/cm2 |

| DIC -150 | 1½”x 1½” | 110 | 1440 | 16 kg/cm2 |

| DIC -200 | 2” x 2” | 250 | 720 | 16 kg/cm2 |

| DIC -250 | 2 ½” x 2 ½” | 333 | 640 | 16 kg/cm2 |

| DIC -300 | 3” x 3” | 500 | 520 | 16 kg/cm2 |

| DIC -400 | 4” x 4” | 750 | 420 | 16 kg/cm2 |

Salient features

- Smooth quite flow

- Reversibility

- Bracket/ Gear box mounting allows free expansion/ contraction alignment not affected

- Insensitive to viscosities

- Easy maintenance

- All metal construction, no contamination

- Built-in reducer offers ideal speed range 240~960 RPM

- Single sealing, external bearing

- Slow speeds ensure better pumping & longer life

- Low noise and pulsation

- Reduced maintenance

PRODUCTS

- Economy RGP/RGX Series

- Heavy Duty DERB/DERN

- Heavy Duty DEW

- Stainless Steel Gear Pumps –DGPSS / SUS

- High Viscous Gear Pumps-HVG

- Fuel Injection DFIG

- Rotary Trachodial Pump DIL

- Internal Gear Pumps with Crescent-DIC

- SS Tri Lobe Pumps Economy – DELB

- Rotary Shuttle Block Pump

- Progressive Cavity Screw Pumps

- Twin Screw Pumps

- Triple Screw Pumps

- Stainless Steel Hand Operated Rotary Barrel / Drum Pumps