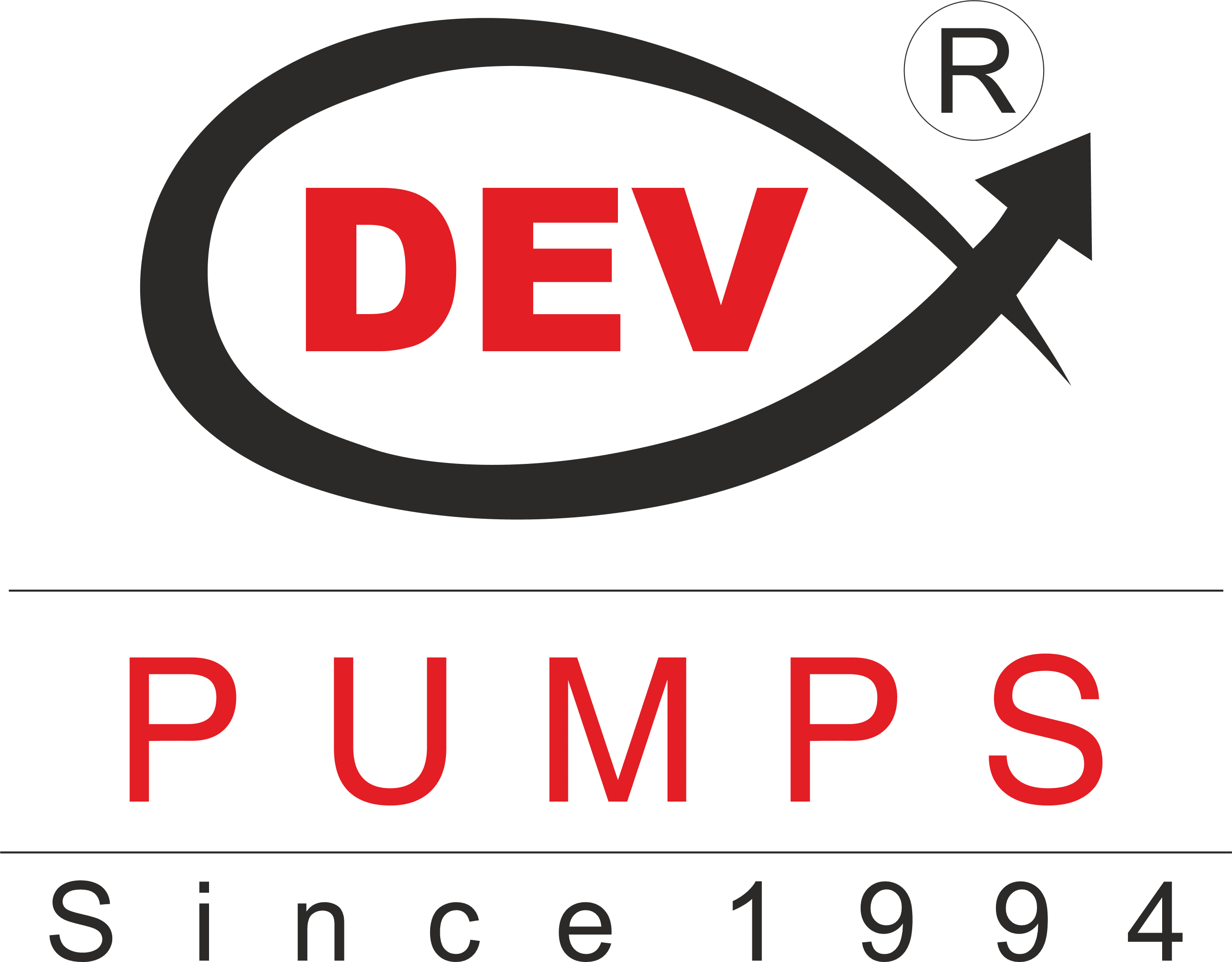

Stainless Steel Rotary Lobe Pump Manufacturer

Dev Engineers a leading manufacturer & supplier of SS Rotary Lobe Pump, SS Lobe Pump, Stainless Steel Rotary Lobe Pump in Ahmedabad, Delhi, Mumbai, Kolkata, Chennai, Bangalore, Indore, Ludhiana, Pune, and Coimbatore.

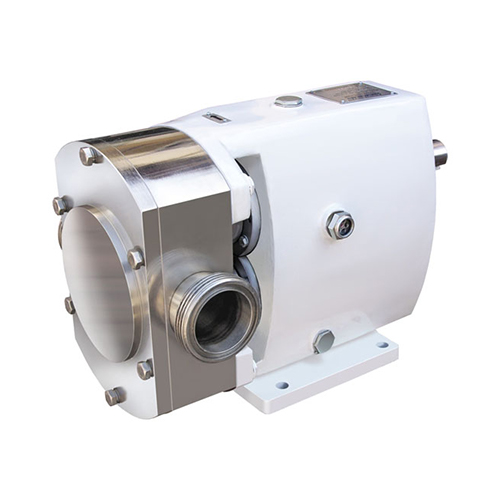

We provide excellent quality of Stainless Steel Rotary Lobe Pump.We have efficient production and Manuafcturing capacity. we are supplier of a top-notch SS lobe pumps which are manufactured at reasonable costs to retailers or distributors for sale. Our manufactured pumps are light weighted and self priming SS Lobe pump.

Working Principle of SS Lobe Pumps

The pump consists of two synchronized rotors present in Lobe pump, this lobe rotate in opposite directions inside a casing. The rotors have lobes that interlock and create a series of cavities, when the cavities move the liquid moves from the inlet side to the outlet of the lobe pump. The cavities have a decreasing volume, it creates a vacuum that sucks the liquid into the pump. The liquid present in pump is then forced out towards the outlet side as the cavities become smaller.

Types of SS Rotary Lobe Pumps

- Bi Stainless Steel Lobe Pump

- Tri Stainless Steel Lobe Pump

“ DEV ” DELB Series Stainless Steel Rotary Lobe Pumps are positive displacement pump technology used widely across the pharmaceutical, food and beverage industries. The pumps action means they are capable of handling shear sensitive materials with low shear.

The rotors are provided with so-called lobes, which rotate past each other without touching each other. The shape of the lobes can vary and the number of lobes can also differ. Due to this design, the lobes of the two rotors intertwine, thereby pumping the liquid in axial direction.

Lobe contact is prevented by external timing gears located in the gearbox. Pump shaft support bearings are located in the gearbox, and since the bearings are out of the pumped liquid. As the lobes come out of mesh, they create expanding volume on the inlet side of the pump. Liquid flows into the cavity and is trapped by the lobes as they rotate. Liquid travels around the interior of the casing in the pockets between the lobes and the casing and it does not pass between the lobes. Finally, the meshing of the lobes forces liquid through the outlet port under pressure.

Salient Features of SS Rotary Lobe Pumps

- These SS rotary Lobe pumps can either be horizontal or vertical foot mounted as per requirement.

- Can be provided with geared motor or with built – in speed reducer.

- The sealing options provided in this series are either mechanical seal or lip seal, as per the application and requirement.

- The standard direction of rotation is anti-clockwise from the pump shaft end with left IN and right OUT configuration.

- The number of lobes per rotor varies from 2 to 6.

- More the number of lobes, higher the chances of less pulsating discharge.

- Max. Capacity up to 100 m3/hr.

- Handle Viscosity up to 200000 cps.

- Standard Max. Temperature to 110 Deg C.

- Jacketing Feature available if liquid has Crystallisation nature.

- All Wetted Parts AISI 316.

- Hard Face Hygienic Mechanical Seals.

- Suction & Discharge Ports available in Tri-clover / Dairy SMS / BSP Screw End / Flange End as per request.

SS Rotary Lobe Pump Advantages

- Easy maintenance.

- Minimum internal losses and excellent self - suction capabilities.

- Low power consumption and high volumetric efficiency.

- Robust Construction.

- Great CIP / SIP and anti-corrosive properties.

- Less numbers of moving parts.

Applications of SS Rotary Lobe Pump

DLB Series SS Rotary Lobe Pump are Frequently used in food, dairy & pharma application because the handle solids without damaging the products and without shearing

Ideal for Pumping Highly Viscous liquids like Butters, Toothpaste, Chocolates, Fruit Pulps, Fats & Oils, Yeast Slurry, Sugar Syrups, Crease , Meat Chunk, Soup & Sauces, Resins, Jams, Jellies, Chocolate Mix, Ice Creamm Shampoo, Cheese, Face Cream, Lotions, Baby foods, Tomato ketchup, Fruit juice etc.

- Food processing.

- Beverages.

- Dairy Produce.

- Personal Hygiene Products.

- Pharmaceutical.

- Chemical.

- Industrial.

SS Rotary Lobe Pump Technical Specification

| Pump Model No. | Port Size Standard Suc x Disch. | Capacity in LPM @ 100 rpm | Max. Speed RPM | Max. Pressure In Kg/cm2 |

|---|---|---|---|---|

| DLB-100 | 1” x 1” | 08 | 1000 | 7.0 |

| DLB-150 | 1 ½” x ½” | 18 | 1000 | 7.0 |

| DLB-200 | 2” x 2” | 38 | 1000 | 7.0 |

| DLB-250 | 2 ½” x 2 ½” | 79 | 1000 | 7.0 |

| DLB-300 | 3” x 3” | 168 | 650 | 7.0 |

| DLB-400 | 4” x 4” | 354 | 550 | 7.0 |

PRODUCTS

- Economy RGP/RGX Series

- Heavy Duty DERB/DERN

- Heavy Duty DEW

- Stainless Steel Gear Pumps –DGPSS / SUS

- High Viscous Gear Pumps-HVG

- Fuel Injection DFIG

- Rotary Trachodial Pump DIL

- Internal Gear Pumps with Crescent-DIC

- SS Tri Lobe Pumps Economy – DELB

- Rotary Shuttle Block Pump

- Progressive Cavity Screw Pumps

- Twin Screw Pumps

- Triple Screw Pumps

- Stainless Steel Hand Operated Rotary Barrel / Drum Pumps